Learn more about the different possibilities of marking.

A solid carbide pin oscillates by pneumatic and electronic means. It is moved by two carriages in the x and y direction and strikes the material by an up and down movement. Depending on the impact frequency the marking either becomes a continuous or a single dotted line – perfect for characters, logos or two-dimensional codes, e.g. Data Matrix Code.

The force produced by the single dot marks is negligible. Due to this it is possible mark pressure sensitive, thin-walled, coated, hollow and arched work pieces. The system is suitable for almost all materials – also hardened steel!

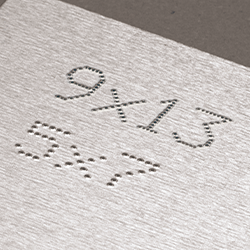

As an alternative variation of the dot peen marking, the marking of single dot characters works also through a carbide marking pin which works pneumatically or electrically. Single dots are achieved by the defined up and down movement of the marking pin. Through to the exact definition of the dots, the matrix fonts are produced in the uni-form size of 5 x 7 or 9 x 13. Other fonts are additionally available.

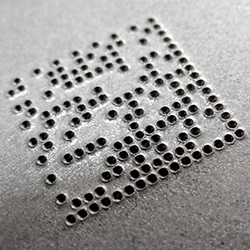

The Data Matrix Code makes it possible to display a lot of information in tight marking areas, on difficult interfaces and in fast production lines. A 2D-Code is considered as "secure" data transmission and can be reconstructed by Reed-Solomon error correction even if up to 25% of the code has been destroyed.

Benefits of the Data Matrix Code:

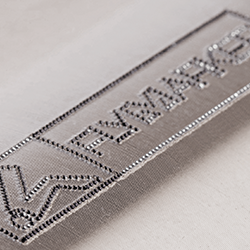

An appealing logo remains in memory and links expectations and experiences with the company. Also in the metal processing industry, products are often provided with company logos. MARKATOR offers the possibility to create and mark individual customer logos. With the help of a special developed logo software, customer logos can be created very precisely.

MARKATOR offers the perfect solution with its marking systems. Depending on the customer's requirements, logos can be marked with all marking systems.